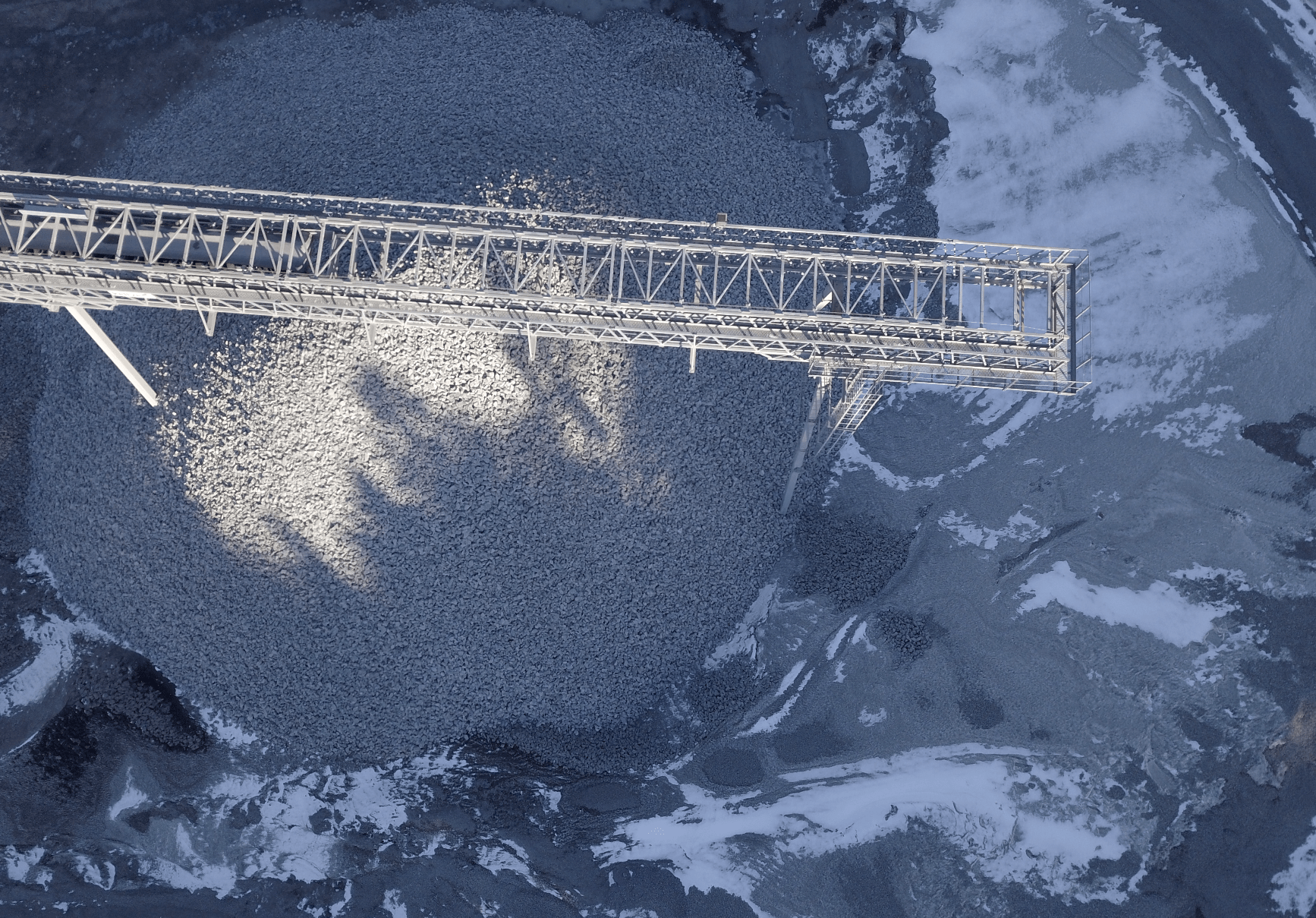

Did you know that excavators, diggers and other construction machinery are not only sending vast amounts of emissions – but also data – to the cloud? We teamed up with Feiring Bruk to explore how this data could be utilized for a smarter, more sustainable, and more profitable construction site.

🤔 The challenge

The engineering and construction (E&C) industry is growing rapidly, but is it technologically developing at the same pace? While the top lines are growing, E&C companies are facing pressure on their net profits due to cost and efficiency demands from public and private customers. Being a leading player in the Norwegian E&C space, Feiring Bruk aimed to play a part in solving this problem with existing data – for themselves and the industry as a whole.

👷 Our approach

We teamed up with Feiring Bruk to understand the needs of large E&C corporations, and both our access to existing data and the business value of on-site utilization of this information. Together with the top management of Feiring Bruk we explored the possibility to collect, validate and combine API-data from OEM’s into one data platform, and how this information could be used for efficiency improvement and even equipment sharing amongst industry players.

«Reodor helped us both understand the great potential of data in our industry, as well as make sure we entered this project with a lean approach – constantly validating needs, opportunities and other hypotheses step-by-step. That way we could build this venture with minimal risk.» — Knut Ollendorff, CEO Feiring bruk

🌟 The results

After validating our data acquisition possibilities through a number of real-life tests, and gaining confidence in the need for equipment sharing through an MVP introduced to market, we moved forward with establishing Fremby as a joint venture. Fremby aims to collect and combine data sets, and build digital solutions that utilize this information for resource optimization in the E&C industry – good for both the environment and the bottom line.